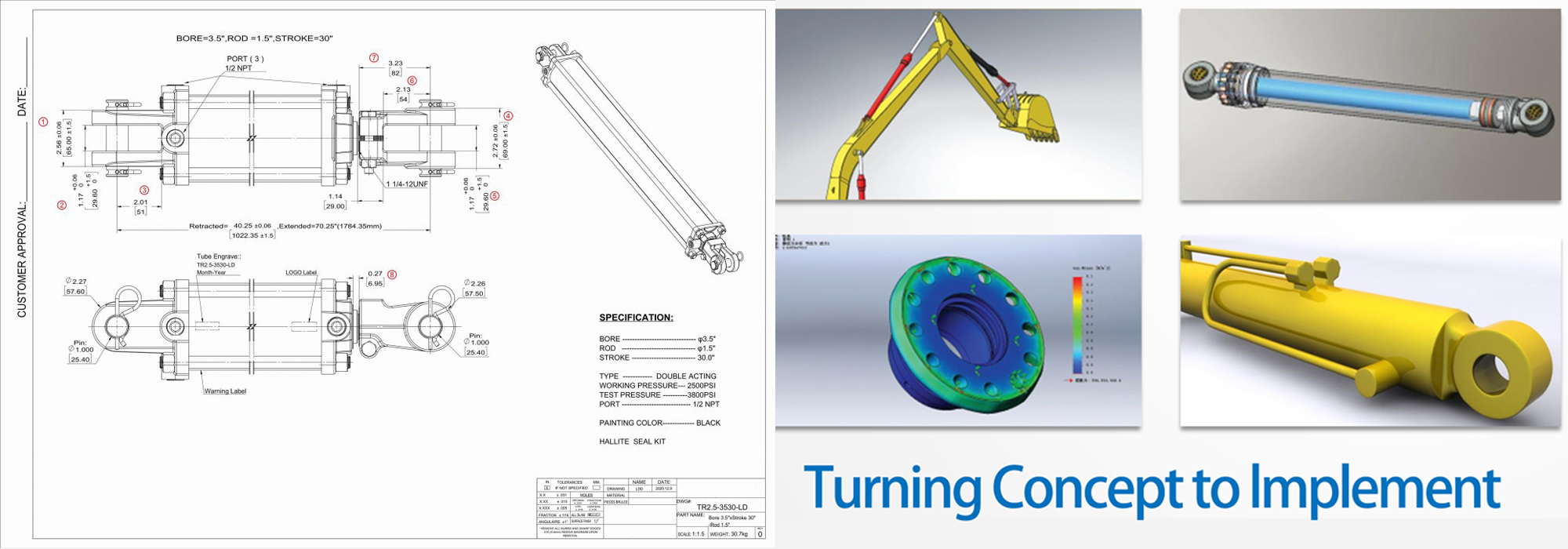

We also can provide customized cylinder that just for you, such as wheel loaders, haul truck, drilling rigs, dozers, etc.

We are committed to providing our customers with the highest quality custom hydraulic cylinder solutions. Our quality products provide you with the reliability and customization needed for optimal hydraulic cylinder performance.Exacting specifications are welcomed. Your requirements come first, and we manufacture purpose-built custom hydraulic cylinders to fit those needs. The cylinder you receive is designed to perform in the intended application.Every detail counts. Our entire company is purpose-built and engineered to move your business. This puts us in control of design, manufacturing, response time, integrity, and quality.

Cylinder tube According to the cylinder pressure and inside diameter size, different steel tube would be selected.

10mm≤ID ≤300mm, choose cold rolled precision seamless tube

300mm≤ID ≤500mm, choose hot rolled seamless tube

500mm≤ID ≤1000mm, choose forged tube

Steel grade : SAE1020, SAE1045, 27SiMn , S355JR, S355J2G3, St52-3, SUS304, SUS316L etc.

Inside boring and honing : roughness R0.2-R0.3

Inside chromed : if necessary ,tube inside chrome plating could be applied Piston rod steel grade : SAE1045, 42CrMo4, SUS410 ,SUS420, SUS304, SUS316L GuangZhou GuoLi Engineering Machinery Co . Ltd ensure that every piece piston rod would be surface hardened before plating, surface hardness is HRC55~60 , plating film thickness is 0.03~0.04mm if there is no other specific requirements. Seal ring and O ring According to the customers’ requirements and working condition, GuangZhou GuoLi Engineering Machinery Co . Ltd would choose suitable seal ring kit, seal ring brand include: Parker, Merkel, NOK, SKF Guangzhou Rubber institute, Taiwan brand etc. GuangZhou GuoLi Engineering Machinery Co . Ltd would supply suitable seal solution for their customer so that hydraulic cylinder has more lifetime, easy maintenance and simple repairing. Tube and flange welding The welding on cylinder tube and flange would be Ultrasonic tested every time, the welding seam would